With ESS systems, there are discrete output alarm signals for both early-warning (low level, advisory) AND a separate high-level (shutdown) alarm is generated when strong motion exceeds the user’s preset thresholds. The high-level output can be used to shut down pumps, close (or open) valves or initiate other automated actions to protect plant personnel, visitors and first responders from hazardous conditions- i.e., toxic/corrosive gases, fuel oils, natural gas (NG)/combustible gases, high (or low) temperature gas & liquid process materials (i.e., cooking oils, steam). On large NG lines feeding buildings the residual pressurized NG behind a closed earthquake valve can ‘feed’ a fire within the owner’s structure- unless vented to atmosphere. Water districts and municipalities can isolate potable water tanks and contain bulk sanitizing chemicals. Just about any process can be automatically controlled at the onset of strong motion shaking. Where the owner’s current non-seismically qualified infrastructure cannot complete the shut down or shut off function at the onset (within a few seconds) of receiving a seismic alarm signal (Saturn S-001, Apollo 2100), ESS’ MSC Master Seismic Controller can be used to power & control actuated valve assemblies throughout the earthquake. Of concern are actuator loss of power and false ‘reset’ or false valve commands caused by failure of the owner’s non-seismically qualified infrastructure (i.e., PLCs re-booting, PLC relay chatter, power failure, comm failures, etc.)- resulting in the incomplete execution of the safety function (mission failure).

With ESS systems, there are discrete output alarm signals for both early-warning (low level, advisory) AND a separate high-level (shutdown) alarm is generated when strong motion exceeds the user’s preset thresholds. The high-level output can be used to shut down pumps, close (or open) valves or initiate other automated actions to protect plant personnel, visitors and first responders from hazardous conditions- i.e., toxic/corrosive gases, fuel oils, natural gas (NG)/combustible gases, high (or low) temperature gas & liquid process materials (i.e., cooking oils, steam). On large NG lines feeding buildings the residual pressurized NG behind a closed earthquake valve can ‘feed’ a fire within the owner’s structure- unless vented to atmosphere. Water districts and municipalities can isolate potable water tanks and contain bulk sanitizing chemicals. Just about any process can be automatically controlled at the onset of strong motion shaking. Where the owner’s current non-seismically qualified infrastructure cannot complete the shut down or shut off function at the onset (within a few seconds) of receiving a seismic alarm signal (Saturn S-001, Apollo 2100), ESS’ MSC Master Seismic Controller can be used to power & control actuated valve assemblies throughout the earthquake. Of concern are actuator loss of power and false ‘reset’ or false valve commands caused by failure of the owner’s non-seismically qualified infrastructure (i.e., PLCs re-booting, PLC relay chatter, power failure, comm failures, etc.)- resulting in the incomplete execution of the safety function (mission failure).

Also, of import is the fact that a broadcast alarm signal does not take into account site specific issues such as local geology, soil conditions, fault geometry, fault orientation or structure fragility. Why shut down your operations just because a broadcast signal declares a M6 earthquake? If the event is 30 miles away and the strongest motion is generally directed away from your facility, it may not produce excessive shaking at your site. If your location is on bedrock, the shaking is often less damaging than the shaking on an ancient lakebed or deep alluvial plain. Therefore, most commercial & industrial facilities are better served by shutting down ONLY if there is excessive ground shaking at their specific location. Earthquakes in Northridge, San Jose, Torrance, Eureka, & Seattle are examples of the benefit of a site-specific response. Newer MSC Master Seismic Controller units are designed to accept the future government broadcast EEW alarm as an optional ‘ENABLE’ signal for the high-level seismic shutdown alarm. If the owner is highly conservative, MSC-series controllers can alternatively perform a logical ‘OR’ function with the broadcast EEW signal, so that, EITHER the broadcast EEW signal or the owner’s site-specific seismic sensor (in the MSC seismic controller) can initiate a shutdown sequence.

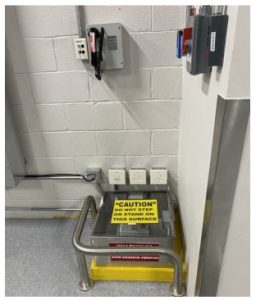

Alternatively, if the end-user only requires normally open or normally closed alarm relay contacts to change state when peak acceleration exceeds a pre-set threshold (i.e., initiate a PA broadcast), the Saturn S-001 or Apollo 2100 Seismic Switches will do the job. These instruments are available in horizontal (standard) or vertical mount. Note: vertical mount should be carefully considered as there is the potential for pre-mature actuation from the resonant response of the wall ‘amplifying’ the input energy. It is preferable to mount the instrument on an inertial mass such as a tank ring wall, building foundation or isolated (free field) concrete housekeeping pad.

In some cases, just a few seconds of warning could make a difference. Imagine operating a forklift in an aisle stacked high with flammable, toxic or corrosive materials- or just plain heavy inventory! Detecting the P-wave at the onset of the strong motion within the blind zone can provide personnel with a warning before the gov’t broadcast alarm is received.

For more information, please feel free to contact us.

Early warning is currently available by either subscribing to a signal broadcast by a government agency/university (i.e. USGS ‘ShakeAlert’ EEW system) or, by in-situ detection of the arrival of the earthquake’s ‘p-wave’- which travels faster than the typically more damaging s-waves. There are a number of variables which make it difficult to say which system provides the greatest advance warning. Certainly, an alarm signal broadcast via radio waves will travel fast and far- with the potential to notify a large, exposed population. In fact, current seismic networks can roughly project what the magnitude of the event will be after just the first few seconds of shaking! However, depending upon the distance of the closest seismic station to the earthquake focus and alarm propagation times to the end-user, it is conceivable that 5, 10- even 20 seconds might pass between the actual start of the event and the receipt of a broadcast alarm signal (the blind zone). If you are within 30 km from the focus you might not get very much ‘useable’ advance warning from a broadcast-based system- which is unfortunate because this ‘zone’ will generally be subject to the strongest ground motion by BOTH the P-wave and the S-wave. Also, the broadcast warning signal must be converted into an alarm signal applicable to your operation- which adds more propagation delay. Some argue that broadcast signals increase the potential for false positives or other, unnecessary shutdowns. However, in the ‘blind zone’, a ‘site-specific’ seismic switch (i.e. Saturn S-001, Apollo 2100 or MSC instruments) would trip on the arrival of the p-wave and provide critical seconds of warning (initiating an automated response) before the more damaging s-wave arrived- and BEFORE the government broadcast alarm signal is received. Dr. David J. Wald (USGS NEIC, EERI, SSA and other affiliations) addresses the practical limitations of broadcast EEW in the ‘blind zone’ in a 2019 research paper published in 2020 in the EERI Earthquake Spectra journal. For those interested in a ‘deeper dive’, Dr. Wald’s paper, “Practical limitations of earthquake early warning“, is available here:

Early warning is currently available by either subscribing to a signal broadcast by a government agency/university (i.e. USGS ‘ShakeAlert’ EEW system) or, by in-situ detection of the arrival of the earthquake’s ‘p-wave’- which travels faster than the typically more damaging s-waves. There are a number of variables which make it difficult to say which system provides the greatest advance warning. Certainly, an alarm signal broadcast via radio waves will travel fast and far- with the potential to notify a large, exposed population. In fact, current seismic networks can roughly project what the magnitude of the event will be after just the first few seconds of shaking! However, depending upon the distance of the closest seismic station to the earthquake focus and alarm propagation times to the end-user, it is conceivable that 5, 10- even 20 seconds might pass between the actual start of the event and the receipt of a broadcast alarm signal (the blind zone). If you are within 30 km from the focus you might not get very much ‘useable’ advance warning from a broadcast-based system- which is unfortunate because this ‘zone’ will generally be subject to the strongest ground motion by BOTH the P-wave and the S-wave. Also, the broadcast warning signal must be converted into an alarm signal applicable to your operation- which adds more propagation delay. Some argue that broadcast signals increase the potential for false positives or other, unnecessary shutdowns. However, in the ‘blind zone’, a ‘site-specific’ seismic switch (i.e. Saturn S-001, Apollo 2100 or MSC instruments) would trip on the arrival of the p-wave and provide critical seconds of warning (initiating an automated response) before the more damaging s-wave arrived- and BEFORE the government broadcast alarm signal is received. Dr. David J. Wald (USGS NEIC, EERI, SSA and other affiliations) addresses the practical limitations of broadcast EEW in the ‘blind zone’ in a 2019 research paper published in 2020 in the EERI Earthquake Spectra journal. For those interested in a ‘deeper dive’, Dr. Wald’s paper, “Practical limitations of earthquake early warning“, is available here: